Training

Vacuum technology and maintenance training for Semiconductor and microelectronics applications

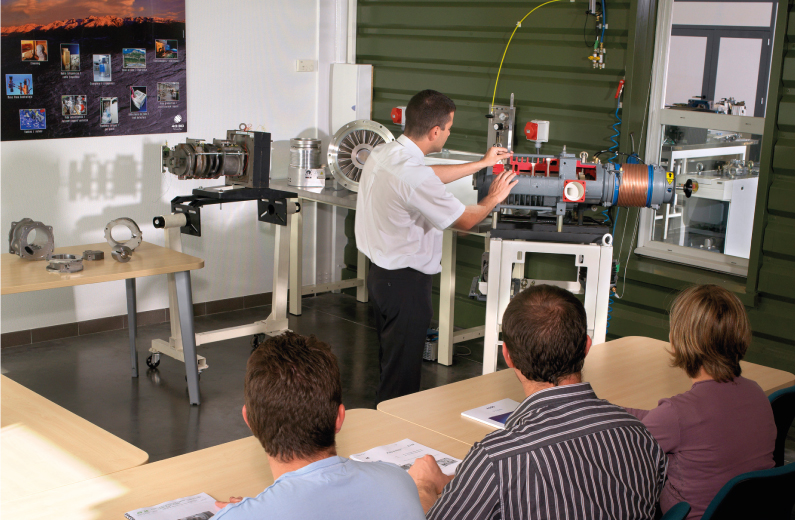

Our training approach

Why choose us

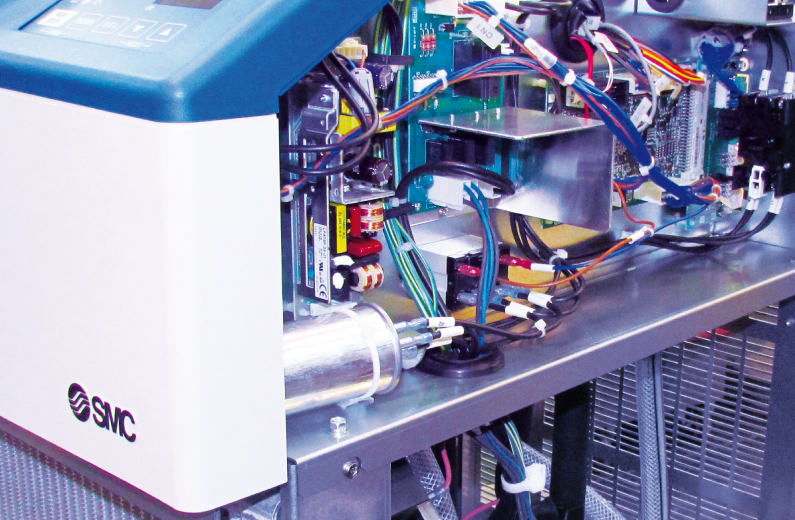

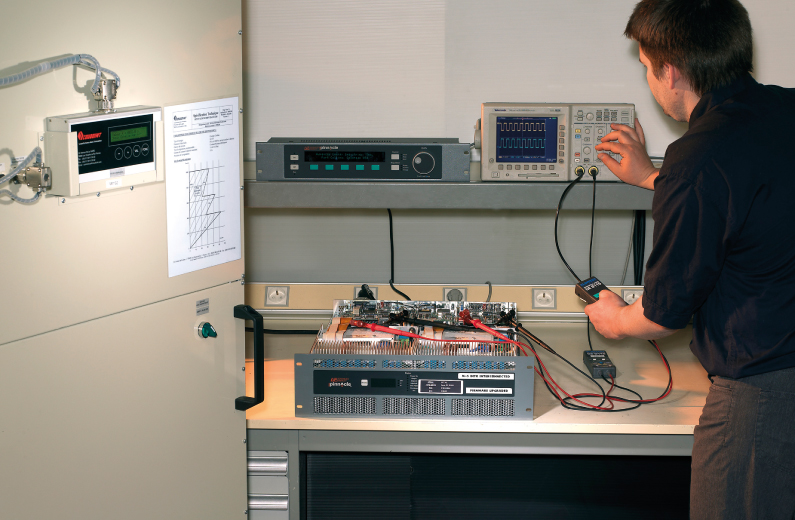

We apply advanced methodologies with hands-on training on real size equipment, tutored e-learning, theoretical courses or skills development programs.

We can offer tailored learning programs to meet a particular corporate strategy, trainees’ proficiency or organizational need. We propose more than 50 technical training modules for semiconductor and microelectronics industry.

We deliver the benefits of both training centers and OEMs, through our thorough training infrastructure and largescale training equipment, all brands, all models available. We build certifying training modules in partnership with renown training institutions.

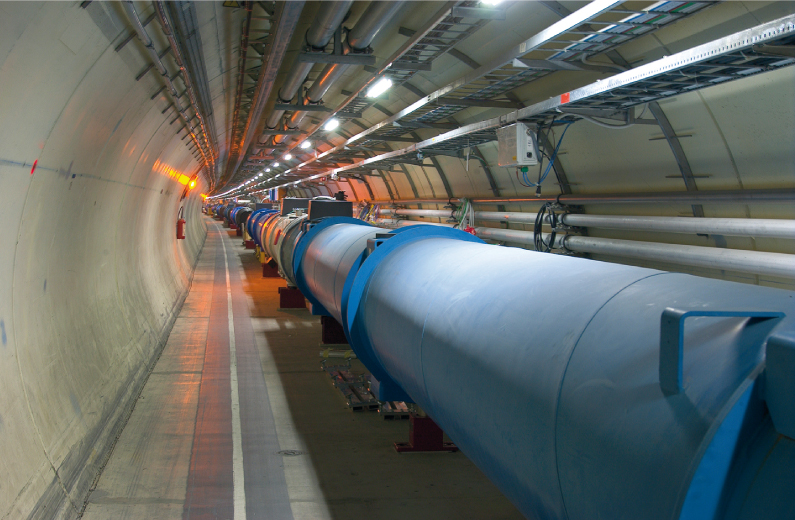

References

- CERN

- ALSTOM

- AGILENT VACUUM

- AIRBUS

- AIR LIQUIDE

- EM MICROELECTRONIC

- ILL

- ESRF

- CNRS

- GENERAL ELECTRIC

- BOLLORE

- CEA

- LETI

- CNES

- CORIAL

- IBA

- IMEC

- INES

- INFINEON

- KOBUS LUMILED

- SAFRAN

- SIEMENS

- SOFRADIR

- SOITEC

- SOURIAU

- ST MICROELECTRONICS

- THALES ALENIA SPACE

- ULIS IR

- VALEO

- WITZENMANN

- X-FAB

Vacuum Technology

- Vacuum physics & technology

- Cleanrooms engineering design

- Helium leak detection

- Residual gas analysis and mass spectrometry

- Mass Flow Controllers

- Ultrasonic cleaning

- Use of wet/dry blasting machine

- Applied English for vacuum technology

- Vacuum systems

Optimal use of equipment

- Helium leak detectors

- Residual gas analysers

- Vacuum instruments & calibration

- Clean concept: behaviour in cleanrooms

Troubleshooting

- Helium leak detectors

- Vacuum systems

- Turbomolecular pumps

- Cryogenic pumps

- Chillers

- Complex instruments

- AstiPure™ pumps (Saint Gobain)

Industrial Radio Frequency

- Principles and techniques

- RF diagnosis on etching & deposition equipment

- RF with technical applications

- HPCVD Rack

- RF-Plasma interaction

AMPS®

(Advanced Management Procedures System)

- Technical procedures writing and management using AMPS®

Specific Maintenance

- Rotary vane pumps

- RF technology and sub-assembly repair

- Cleanroom maintenance

- Roots blowers

Safety

- Chemical risks

- Awareness of risks

- Thin films deposition chambers

- Electrical certification

NDT Helium Leak Testing

- Levels 1, 2 and 3

Mobile learning

Activities on your mobile

E-learning

Videos, quizzes and videoconferences

Mixed formations

Refresher, course, video and quiz exercises online

Training Department

+33 (0)4 76 87 40 30

Our tools and methods

Our vision of the future of training is translated through continuous investment and improvement in teaching tools

- Conversion of our IT to the Cloud model

- New communication and training tools i.e. Skype for Business

- Development of e-learning courses: mooc, virtual classes, forums, quizzes, etc.

- Collaborative mean of knowledge transfer, AMPS®

40-30 Customer-focused training quality management system

- ANALYSING : Needs Analysis / Evaluation quiz to evaluate trainees’ knowledge level

- PREPARING : Course design e-Learning / Planning to optimise the course

- TEACHING : Learning & Training application at customer’s site to learn required skills

- QUALIFYING : Evaluation quiz / Knowledge validation to check knowledge acquisition & deliver a competence certificate

- FOLLOW-UP : Feedback to continuously monitor and improve