How to detect a leak in ITER’s Vacuum Vessel from 2000 entry points?

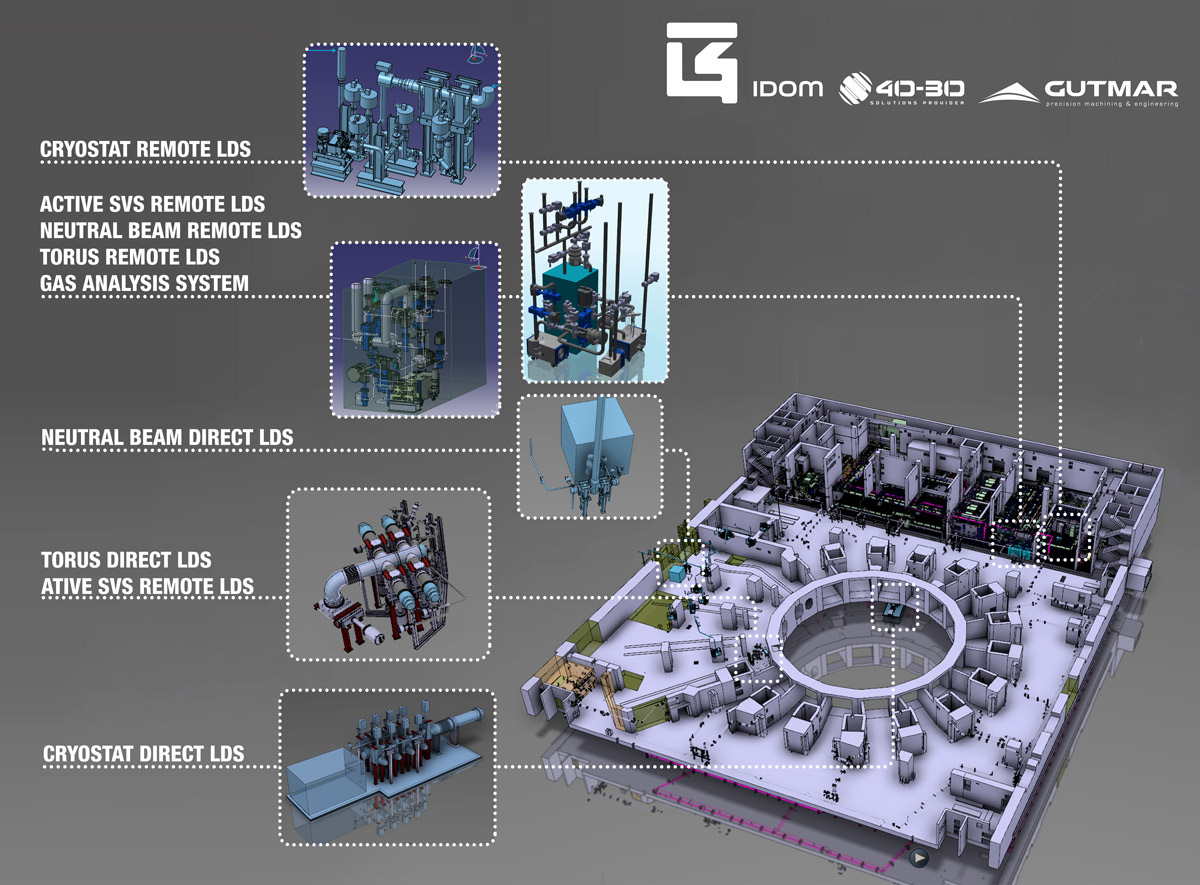

The various leak detection sub-systems (LDS) are aimed at verifying that the stringent leak tightness requirements are achieved in the vacuum vessel, the cryostat and other ITER components that need ultra-high vacuum requirements for proper functioning. © IG4 Retrieved from https://fusionforenergy.europa.eu/

When the ITER machine operates it will be important to maintain the conditions that allow the fusion reaction. For instance, we need to ensure the vacuum in the vessel housing the plasma. Any leak or contamination into the vacuum vessel could disturb the reaction and therefore should be detected as soon as possible.

To do so, a leak detection system is required. F4E is responsible for its procurement, which will allow ITER Organization to detect and monitor any possible leaks. So where could they potentially come from? There are roughly 2000 entry points from the cryostat, the vacuum vessel and the neutral beam.

Using mass spectrometry operating on high resolution, engineers will detect any helium leaks under specific conditions. These include even a seismic event, in an environment with high radiation and powerful magnetic fields complying with the nuclear safety standards applying to ITER. Although mass spectrometry is a well-known and widely used technique for leak detection, the adaptation of this technology to ITER standards is what makes it demanding.

The tendering process to award this contract has been complex, as the selected consortium of companies had to encompass all the knowledge in design, procurement, manufacturing and testing of the system. The consortium that won the contract, named IG4, is led by IDOM, which is in charge of the design of the system. Two SMEs complete the consortium: 40-30, which deals with process and vacuum engineering and equipment specification, and Gutmar, which will manufacture, assemble and test the equipment.

The consortium started to work with F4E in September. But a lot of work had been done previously: “The contract signature on the 13 August was the tip of the iceberg. We spent a whole year to work out the basic functional requirements of the leak detection systems for ITER and to translate them to technical specifications and contract documentation,” stresses Roger Martín, F4E Cryoplant & Fuel Cycle Project Manager.

According to Xabier Ruiz, Director of IDOM Nuclear Services, “The combination of the technical difficulties posed by a first-of-a-kind project and the challenges posed by the pandemic have been so far excellently tackled by the consortium and the team, paving the road for a successful execution.”

Charles Agnetti, CEO of 40-30, adds that “We are really proud to be involved in this high technical project whose target is to harness clean energy for the mankind. For this mission, 40-30 has assigned its most experienced specialists in vacuum technology and processes, leak detection and gas analysis.”

Joan Martorell, CEO of Gutmar, is also enthusiastic about the outcomes of this collaboration: “We are convinced that this innovative and technological project places us at the cutting edge of technology. The alliance with IDOM and 40-30 is indeed very positive to achieve optimal results and will be the beginning of a long term partnership open to future collaborations.”

The total value of the contract is in the range of 17 million EUR and works are expected to run for 3.5 years. Currently, F4E and the contractors are developing the preliminary design, aiming for a preliminary design review in the first half of 2021.

Last News

Préventica 2024

40-30 and Riken Keiki at Préventica 2024, October 8 & 10, 2024 at Eurexpo Lyon.

V2T 2024

40-30 at the 2024 Vacuum Technologies for Tomorrow (V2T) in Grenoble WTC Congress Center on May 29 & 30, 2024.

SEMICON Europa 2022

Visit us at SEMICON Europa 2022 in Munich, from 15th to 18th of November. Visit us at our booth C1-465.