Engineering

40-30 has a proven track record with large engineering projects in the field of vacuum technologies, leak detection, cryogenic, cleaning and vacuum generating equipment for the industries we serve.

Our experienced engineering staff

possesses the credentials and skills to provide you with solutions.

- Design of test benches and test systems dedicated to the maintenance and control of sub-assemblies.

- Reliability of sub-assemblies and equipment. FMEA approach, re-engineering.

- Upgrades, modifications on production equipment.

- Development and adjustment of procedures for decontamination, ultraclean cleaning, degassing.

- Developing, implementing workshop and maintenance equipment.

- Advice in maintenance strategy. Methodology, program, frequency, level of integration.

- Establishing processes and procedures resulting in certification of helium leak detection. NDT qualified personnel according to standard ISO9712-EN 473.

- Designing maintenance procedures.

- Areas of expertise include Vacuum technology, cryogeny, radio frequency, electronic, cleaning…

Application areas

- vacuum technology

- cryogenics

- radiofrequency

- electronics

- cleaning

- Vacuum generating equipment

- …

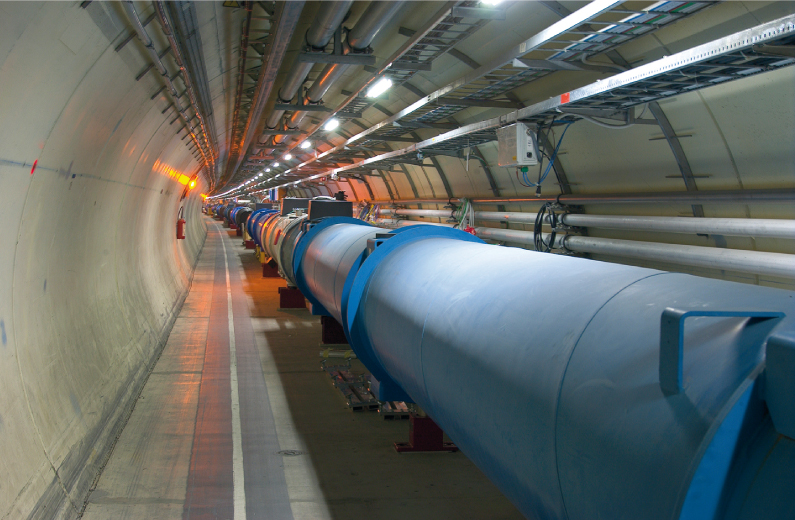

CERN

Large Hadron Collider (LHC),Geneva, Switzerland

- Helium leak test on QRL (27 km)

- Interconnections in the tunnel: 43 000 welds tested (354 leaks detected)

- Assembly and alignment of over 2 km of UHV pipes

- Ultra high vacuum, international environment

LMJ

Laser Megajoule, Barp, France

- Outgassing measurement to analyse the organic pollution

- Cleaning procedure for the mirrors

- Tightness control

- Ultra clean environmen

X-Fel

The European X-Ray Free-Electron Laser, Hamburg, Germany

- Assembly of cryogenic modules

- Specific materials (ISO 5)

- Ultra clean environment

- Specific seals, parts and design

Design of leak test equipment

-

Facility to be tested

-

Stainless steel pool liner of a nuclear plant

-

Constraint

-

Nuclear environment, depth of 12 meters, under water